The Process of Minting Coins

Transforming Metal into Modern Treasures

Did you know that each coin in your pocket has taken a spectacular journey before landing in your hands? The minting process is where raw metal transforms into shiny, spendable currency. It’s like alchemy—but with precision engineering and a touch of artistry!

It all starts with raw materials—often a blend of metals like copper, zinc, and nickel. These alloys are shaped into sheets as smooth as glass. Imagine these sheets being fed into machines that punch out blank discs, known as “planchets.” At this stage, they’re like newborns: full of potential but missing their defining features.

Next comes the most magical part: imprinting. Planchets are sent through high-pressure presses fitted with detailed dies. Think of these dies as stamps loaded with intricate designs—the faces of presidents, powerful symbols, and fine lettering. With a deafening clatter, coins emerge with their dazzling identities.

- Annealing: Planchets are heated to soften them for embossing.

- Rimming: Coins get raised edges to protect their designs from wear.

- Polishing: A final shine makes them irresistible to the hand—and eye!

Every coin tells a story, and its adventure begins right here, amidst fire, force, and finesse.

Design and Production of Coins

The Birth of a Coin: Artistic Brilliance Meets Precision

Have you ever held a coin and wondered about its story—the creativity, craftsmanship, and technology behind that tiny metallic masterpiece? The design and production of coins is less an industrial process and more a mesmerizing blend of art and exacting science.

Creating a coin starts with a spark of brilliance. Designers sketch ideas that will soon represent a nation’s heritage, culture, or history. From the intricate curls of a monarch’s profile to symbolic motifs like soaring eagles or floral patterns, every detail matters. This isn’t just any doodling—designers consider how light will dance off the raised edges or how the tiniest details will remain crisp for decades.

Once the design is perfected, it meets the machines. The process begins with engraving dies, where each coin’s “blueprint” is carved into ultra-hard steel. The precision here is jaw-dropping; some engravings are detailed down to *micrometers*. Then, vast sheets of metal are punched into perfect blanks, polished till they gleam, and struck with tons of force to etch the design.

- Ever noticed the ridges on the side of some coins? Those aren’t just for looks—they prevent counterfeiting.

- And those sharp, shiny edges? That’s the handiwork of state-of-the-art polishing techniques.

From idea to reality, every coin is a tiny, circulating piece of art crafted with care. Next time you grab some change, give it a second glance—it encapsulates not just value but vision.

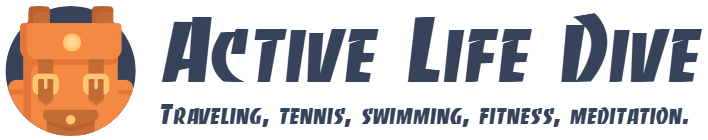

Distribution Channels for Coins

How Coins Find Their Way to Your Hands

Have you ever stopped to think about how a shiny new coin ends up jingling in your pocket? The journey is nothing short of remarkable, and it all begins with meticulous planning and logistics. Once coins roll off the minting presses, their adventure starts with a web of distribution channels designed to get them into circulation quickly and efficiently.

Banks play a starring role here. They act as the gateway for freshly minted coins to enter everyday life. But they’re not alone—there’s a supporting cast too. Did you know that armored transport companies ensure these coins travel securely from mints to financial institutions? It’s a safeguard against loss or mismanagement, as these tiny metal tokens often move in enormous quantities!

- Central banks: They allocate coins based on regional demands and economic activity.

- Commercial banks: These serve as local hubs for businesses and individuals to obtain currency.

- Retailers and vending machine operators: They receive coins directly in bulk so there’s always something to give you as change for your coffee.

Every coin’s path involves a delicate choreography between institutions, all working together to make sure no market runs dry of this humble yet indispensable currency.

Circulation and Usage in the Economy

The Lifeblood of Transactions

Imagine this: a humble coin slipping through your fingers at the coffee shop, only to end up in someone else’s pocket by the afternoon. Coins are not just currency—they’re the unsung heroes keeping the economy humming. From buying a loaf of bread to tipping your favorite street musician, they make countless small but mighty exchanges possible every day.

What’s fascinating is how these little discs of metal weave their way into everyday life. Think of the last vending machine you used or the parking meter you fed—without coins, these simple conveniences would grind to a halt. Coins bridge the gap where cards fall short, often serving rural areas or informal markets where digital payments aren’t an option.

The Ripple Effect of a Coin

Each coin has a ripple effect across industries and households. It can:

- Start as a child’s allowance before becoming change for a taxi driver.

- Get tossed into a donation bucket, funding local charities and causes.

- Be hoarded in grandma’s jar, only to flow back into circulation during the holiday shopping sprees.

Every coin tells a story—of human connection, trade, and trust. The next time you hear the jingle in your pocket, remember: it’s more than spare change; it’s economic energy in motion.

Challenges and Innovations in Coin Lifecycle

Unveiling the Hidden Struggles of a Coin’s Lifetime

Every coin embarks on a journey that’s far from smooth sailing. Imagine the countless hands a single coin might pass through—markets, vending machines, bus fare boxes—all while battling wear and tear. Over time, this constant exchange leads to physical degradation, causing some coins to retire earlier than others. And let’s not forget the “vanishing act” many coins perform, slipping into couch cushions or dusty jars, effectively disappearing from circulation.

The logistics of keeping coins in play can feel like orchestrating a symphony in a windstorm. One major puzzle? Managing supply and demand. At times, certain denominations become scarce while others pile up, unused. The process of recalling, melting down, and re-minting these stagnant coins is a drain on both resources and time.

Innovative Twists Breathing New Life into Coins

Yet, where there are challenges, there’s room for invention. Enter innovations such as:

- Durable alloys that make coins last longer in circulation.

- Cash recycling systems powered by cutting-edge AI to track and redistribute unused change.

These breakthroughs breathe fresh energy into the coin lifecycle, proving that even the smallest currency has room to evolve.